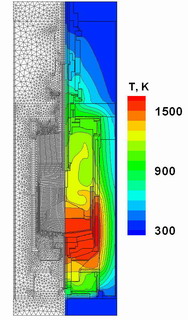

Fig. 1.

The computational grid and the temperature distribution in the VCz

system for 4" GaAs crystal growth

|

Modeling of the VCz GaAs growth

Numerical investigation of the effect of radiative heat exchange

in the encapsulant was performed using CGSim software with respect to

its influence on the crystallization front geometry during

encapsulated GaAs Czochralski growth with the vapor pressure control

[1]. Radiative heat exchange, conductive heat exchange and turbulent

flows within the Reynolds-averaged Navier-Stokes (RANS) equations are

considered in a conjugated way. Advanced analysis of heat transfer

and melt/encapsulant flows in the crystallization zone is performed

within updated 3D unsteady approach based on the LES technique. The

3D analysis is applied to describe the real melt flow behavior, which

is not always possible within the RANS approach usually resulting in

steady state axisymmetric flow patterns. It should be mentioned that

the 3D flows of the melt and encapsulant were considered in a way

with conjugated heat and momentum exchange.

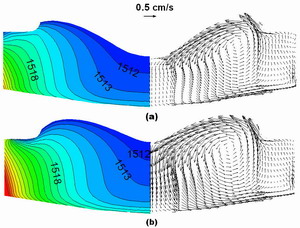

Fig. 2.

The temperature distributions and the flow patterns obtained in the 2D

computations (VCz system for 4" GaAs crystal growth). The encapsulant

is considered as an opaque (a) or a transparent (b) medium.

|

The effect of optical

properties of the encapsulant layer is additionally considered in two

opposite cases to reveal their contribution to the crystallization

front formation. It is evident that optical properties

of the encapsulant affect both the temperature distribution and melt

velocity. In the case of transparent encapsulant, the temperature

difference in the melt is higher due to the intensified heat

transport through the melt-encapsulant interface. For the case of

opaque encapsulant, a lower temperature difference in the melt is

sufficient to maintain the desired crystallization rate.

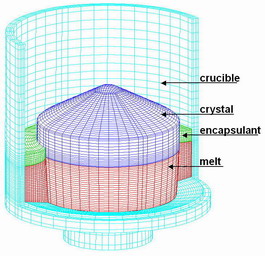

Fig. 3.

An example of the 3D block-structured computational grid for

crystallization zone.

|

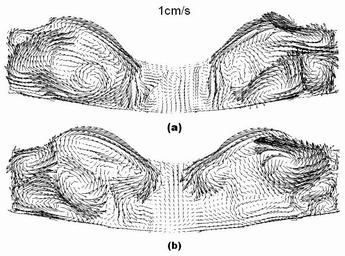

Fig. 4.

The instantaneous flow patterns obtained in the 3D computations

(VCz system for 4" GaAs crystal growth). The encapsulant is

considered as an opaque (a) or a transparent medium (b).

|

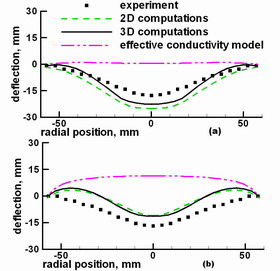

Fig. 5.

The comparison of the computed and experimental crystallization

front shape (VCz system for 4" GaAs crystal growth). The encapsulant

is considered as an opaque (a) or a transparent medium (b).

|

Of high interest is the fact that there

are significant differences between the results of the flow

prediction using the steady 2D and unsteady 3D approaches. The 2D

RANS approach predicts that the melt flow is practically suppressed

in the melt periphery under the encapsulant layer, which is not

proved, analyzing the data provided by more general 3D computations.

Using both approaches, the melt flow under the crystal is described

in a similar manner; however, there is a certain difference near the

axis of symmetry. 3D unsteady modeling revealed small turbulent

structures near the axis; whereas there is only downward melt motion

in the data of RANS analysis. The effect of optical properties of the

encapsulant, obtained in 3D analysis, has showed that the increase in

temperature difference in the melt for the case of transparent

encapsulant layer results in intensifying melt fluctuating velocity,

especially, under the encapsulant.

One can see that the optical properties of the encapsulant

noticeably affect the crystallization front shape formation. Note

that both 2D and 3D flow models predict overestimated interface

deflection for the case of opaque encapsulant and underestimated

deflection for the case of transparent encapsulant, in such a way

that the adequate result should be obtained by means of a relevant

semitransparent optical model.

References

[1] O.V. Smirnova, V.V. Kalaev, Yu.N. Makarov, Ch. Frank-Rotsch,

M. Neubert, P. Rudolph, J. of Crystal Growth 266(2004) 67-73

|