PVT Growth of Wide-Bandgap Semiconductors. Overview

Activity of our company in the growth of wide bandgap semiconductors include development and application of advanced models of sublimation growth, or Physical Vapor Transport (PVT), of Silicon Carbide (SiC), Aluminum Nitride (AlN), and Gallium Nitride (GaN). We focus on specific features of PVT growth providing solutions to a variety of problems arising in growth technology, predicting the thermal fields in the growth system, crystal shape after the growth, temporal evolution of the growth rate and source structure during the growth, defect evolution, etc.

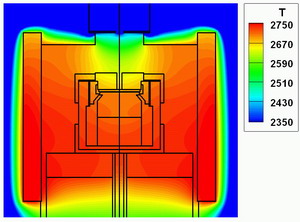

Fig.1. Schematic view of a SiC

growth chamber. |

Sublimation growth occurs at high temperatures in closed or semi-closed crucibles and involves sublimation of source polycrystalline material placed in the hot zone, its transport through the growth chamber and deposition on the relatively cold seed. In growing bulk wide bandgap crystals by PVT, the quality of the grown material is controlled by a particular temperature distribution in the growth system, which affects simultaneously many factors like crystal shape, source evolution, parasitic deposition on the crucible walls, etc.

An inherent feature of bulk crystal growth technique is its non-steady-state character. Several factors, first of all, evolution of the crystal shape and source structure, result in a gradual change of the growth rate and crystal quality.

Experimental optimization of the growth process takes normally much effort and is time-consuming. Thus, modeling is quite beneficial for growth system design and finding optimal growth condition if the models used allow for important features of the process.

Fig.2. A typical temperature distribution in

the growth system. |

- Heat transfer by conduction, convection and radiation mechanisms

- Gas flow dynamics

- Species diffusion

- Surface chemical reactions

- Evolution of the crystallization fronts

- Mass exchange between the crucible and the ambient through slits or pores

- Evolution of the porous source

- Crystal faceting

- Dislocation dynamics

Of primary importance in PVT growth systems is temperature control. The experimental temperature inside the growth system is controlled in one or two points via pyrometric windows, which provide to control the outer crucible temperature. However, experimental measurement of the temperature inside the crucible and the temperature distribution is unavailable. Theoretical analysis of temperature distribution is made by detailed numerical modeling accounting for heat conduction and radiation.

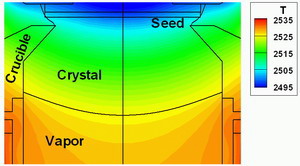

Fig.3. Crystal shape and temperature

distribution in the growth chamber after the growth. |

The temperature analysis is followed by the prediction of the mass transport

which provides information on the crystal growth rate distribution, source evaporation

and eventually yields crystal shape after the growth. The chemical interaction

of the vapor with crystal surface, source and walls is described applying an original

quasi-thermodynamic model, which relates the total flux of the each species from vapor

onto surface to its partial and equilibrium pressures by the Hertz-Knudsen equation,

assuming the equilibrium pressures to be governed by the mass action law.

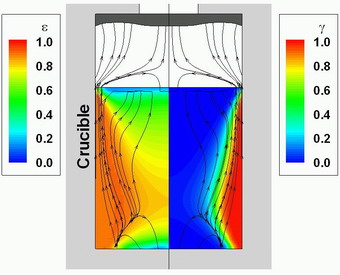

Fig.4. Flow pattern and distribution of the Powder Porosity (left) and Graphitization Degree

(right). |

A 2D model of the powder charge evolution has been developed to account for the effect of the evolution of powder structure during the growth. Intensive powder evaporation occurs at hot crucible walls, the reactive species are transported to the relatively cold powder zones where recrystallization is predicted.

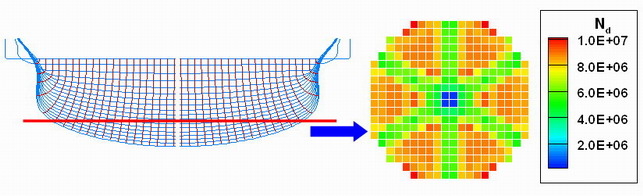

An important aspect of bulk growth modeling is prediction of dislocation dynamics,

which include formation of gliding dislocations due to thermal elastic stress in

the growing crystal and propagation of threading dislocation from the seed into

the crystal bulk. An anisotropic thermal elastic model is applied to hexagonal

crystals. Propagation of threading dislocation is considered for {1010}<1210>

and {1010}<0001> slip systems.

Fig.5. Distribution of threading

dislocations in a SiC wafer cut from the boule shown at the left hand side. |

Silicon Carbide

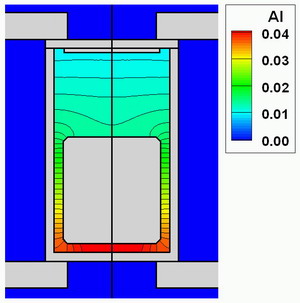

Fig.6. Al mass fraction distribution

in the gas cell. |

Aluminum Nitride

AlN crystals are normally grown by PVT in W or BN containers at high temperatures up to 2500°C. The vapor includes gaseous Al and N2, with polycrystalline AlN serving as a source of both Al and Nitrogen species.

High operating temperatures are required by kinetic limitation of the N2 adsorption/desorption rate, which represents is the major difference between surface kinetics of SiC and AlN growth. This effect is accounted for by introducing temperature dependent N2 sticking coefficient, which is evaluated using the available data on Langmuir evaporation of AlN.

Of interest is the problem of oxygen incorporation into the growing crystal.

A study of the effect of oxygen contained in the vapor has revealed a noticeable

effect on the AlN growth rate at low temperatures.

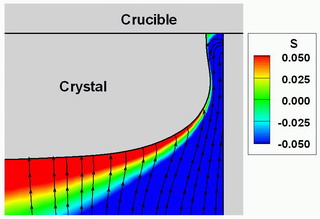

Gallium Nitride

Fig.7. Local streamline patterns

and supersaturation distributions near the slit under the crucible lid.

|

Theoretical analysis providing prediction of the Ga transport between the source and the substrate is carried out accounting for Ga diffusion, convection in the growth chamber enhanced by H2 generation at the source surface, multiple channel Ga desorption and generation of Ga droplets on the source surface.

References

2004

I.D. Matukov, D.S. Kalinin, M.V. Bogdanov, S.Yu. Karpov, D.Kh. Ofengeim, M.S. Ramm, J.S. Barash, E.N. Mokhov, A.D. Roenkov, Yu.A. Vodakov, M.G. Ramm, H. Helava, Yu.N. Makarov, Modeling of Facet Formation in SiC Bulk Crystal Growth, J. Crystal Growth 266 (2004) 313-319.

A.V. Kulik, M.V. Bogdanov, S.Yu. Karpov, M.S. Ramm, Yu.N. Makarov, Theoretical Analysis of the Mass Transport in the Powder Charge in Long-Term Bulk SiC Growth, Mat. Sci. Forum 457-460 (2004) 67-70.

I.D. Matukov, D.S. Kalinin, M.V. Bogdanov, S.Yu. Karpov, D.Kh. Ofengeim, M.S. Ramm, J.S. Barash, E.N. Mokhov, A.D. Roenkov, Yu.A. Vodakov, M.G. Ramm, H. Helava, Yu.N. Makarov, Faceted Growth of SiC Bulk Crystals, Mat. Sci. Forum 457-460 (2004) 63-66.

P.J. Wellmann, Z. Herro, S.A. Sakwe, P. Masri, M. Bogdanov, S. Karpov, A. Kulik, M. Ramm, and Yu. Makarov, Analysis of Graphitization during Physical vapor Transport Growth of Silicon Carbide, Mat. Sci. Forum 457-460 (2004) 55-58.

M.V. Bogdanov, D.Kh. Ofengeim, A.I. Zhmakin, Industrial Challenges for Numerical Simulation of Crystal Growth, Centr. Eur. Jour. Phys. 2 (1) (2004) 183-203.

2003

M.V. Bogdanov, S.E. Demina, S.Yu. Karpov, A.V. Kulik, M.S. Ramm, Yu.N. Makarov, Advances in modeling of wide-bandgap bulk crystal growth, Cryst. Res. Technol. 38 (2003) 237-249.

Bogdanov M.V., Karpov S.Yu., Kulik A.V., Ramm M.S., Makarov Yu.N., Schlesser R., Dalmau R.F., Sitar Z. Experimental and theoretical analysis of heat and mass transport in the system for AlN bulk crystal growth. Materials Research Society Symposium Proceedings, Vol.743, p.L3.33, (2003)

Bogdanov M.V., Demina S.E., Karpov S.Yu., Kulik A.V., Ofengeim D.Kh., Ramm M.S., Mokhov E.N., Roenkov A.D., Vodakov Yu.A., Makarov Yu.N., Helava H., Modeling analysis of free-spreading sublimation growth of SiC crystals. Materials Research Society Symposium Proceedings, Vol.742, p.K1.3, (2003)

2001

A.V. Kulik, M.V. Bogdanov, D.Kh. Ofengeim, S.K. Kochuguev, S.E. Demina, S.Yu. Karpov, A.I. Zhmakin, M.S. Ramm, Yu.N. Makarov, Modeling and Optimization of SiC Bulk Crystal Growth by Sublimation Technique, Proc. of the Forth Int. Conf. on Single Crystal Growth on Heat & Mass Transfer, p.698 (Obninsk, Sept.24-29, 2001).

Kulik A.V., Demina S.E., Kochuguev S.K., Ofengeim D.Kh., Karpov S.Yu., Vorob'ev A.N., M.V. Bogdanov, Ramm M.S., Zhmakin A.I., Alonso A.A., Gurevich S.G., Makarov Yu.N., Inverse-computation design of a SiC bulk crystal growth system. Materials Research Society Symposium Proceedings, Vol.640, p.H1.6.1-H1.6.6, (2001)

Karpov S.Yu., Kulik A.V., Segal A.S., Ramm M.S., Makarov Yu.N. Effect of reactive ambient on AlN sublimation growth. Physica Status Solidi (a), Vol.2 188, p.763-767, (2001)

Karpov S.Yu., Kulik A.V., Ramm M.S., Mokhov E.N., Roenkov A.D., Vodakov Yu.A., Makarov Yu.N. AlN crystal growth by sublimation technique. Materials Science Forum, Vol.353-356, p.779-782, (2001)

Bogdanov M.V., Galyukov A.O., Karpov S.Yu., Kulik A.V., Kochuguev S.K., Ofengeim D.Kh., Tsirulnikov A.V., Zhmakin I.A., Komissarov A.E., Bord O.V., Ramm M.S., Zhmakin A.I., Makarov Yu.N., Virtual reactor: a new tool for SiC bulk crystal growth study and optimization. Materials Science Forum, Vol.353-356, p.57-60, (2001)

Karpov D.S., Bord O.V., Ramm M.S., Karpov S.Yu., Zhmakin A.I., Makarov Yu.N., Mass transport and powder source evolution in sublimation growth of SiC bulk crystals. Materials Science Forum, Vol.353-356, p.37-40, (2001)

Bogdanov M.V., Galyukov A.O., Karpov S.Yu., Kulik A.V., Kochuguev S.K., Ofengeim D.Kh., Tsirulnikov A.V., Ramm M.S., Zhmakin A.I., Makarov Yu.N., Virtual reactor as a new tool for modeling and optimization of SiC bulk crystal growth. Journal of Crystal Growth, Vol.225, p.307-311, (2001)

2000

Karpov S.Yu., Kulik A.V., Zhmakin I.A., Makarov Yu.N., E.N. Mokhov, Ramm M.G., Ramm M.S., Roenkov A.D., Vodakov Yu.A., Analysis of sublimation growth of bulk SiC crystals in tantalum container. Journal of Crystal Growth, Vol.211, p.347-351, (2000)

Selder M., Kadinski L., Makarov Yu., Durst F., Wellmann P., Straubinger T., Hofmann D., Karpov S., Ramm M., Global numerical simulation of heat and mass transfer for SiC bulk crystal growth by PVT. Journal of Crystal Growth, Vol.211, p.333-338, (2000)

Segal A.S., Karpov S.Yu., Makarov Yu.N., Mokhov E.N., Roenkov A.D., Ramm M.G., Vodakov Yu.A. On mechanisms of sublimation growth of AlN bulk crystals. Journal of Crystal Growth, Vol.211, p.68-72, (2000)

Segal A.S., Vorob'ev A.N., Karpov S.Yu., Mokhov E.N., Ramm M.G., Ramm M.S., Roenkov A.D., Vodakov Yu.A., Makarov Yu.N., Growth of silicon carbide by sublimation sandwich method in the atmosphere of inert gas. Journal of Crystal Growth, Vol.208, p.431-441, (2000)

Zhmakin I.A., Kulik A.V., Karpov S.Yu., Demina S.E., Ramm M.S., Makarov Yu.N., Evolution of thermoelastic strain and dislocation density during sublimation growth of silicon carbide. Diamond and Related Materials, Vol.9, p.446-451, (2000)

1999

Karpov S.Yu., Zimina D.V., Makarov Yu.N., Mokhov E.N., Roenkov A.D., Ramm M.G., Vodakov Yu.A. Sublimation growth of AlN in vacuum and in a gas atmosphere. Physica Status Solidi (a), Vol.176, p.435-438, (1999)

Ramm M.S., Mokhov E.N., Demina S.E., Ramm M.G., Karpov S.Yu., Roenkov A.D , Vodakov Yu.A., Segal A.S., Vorob'ev A.N., Kulik A.V., Makarov Yu.N., Optimization of sublimation growth of SiC bulk crystals using modeling. Materials Science and Engineering, Vol.B61-62, p.107-112, (1999)

Segal A.S., Vorob'ev A.N., Karpov S.Yu., Makarov Yu.N., Mokhov E.N., Ramm M.G. , Ramm M.S., Roenkov A.D., Vodakov Yu.A. , Zhmakin A.I., Transport phenomena in sublimation growth of SiC bulk crystals. Materials Science and Engineering, Vol.B61-62, p.40-43, (1999)

Makarov Yu.N., Demina S.E., Karpov S.Yu., Kulik A.V., Mokhov E.N., Ramm M.G., Ramm M.S., Roenkov A.D., Vodakov Yu.A., Zhmakin A.I., Specific features of sublimation growth of bulk SiC crystals in tantalum container. International Conference on Silicon Carbide and Related Materials, Abstract N 247., (1999)

1998

Karpov S.Yu., Makarov Yu.N., Ramm M.S., Talalaev R.A. Analysis of gallium nitride growth by gas-source molecular beam epitaxy. Journal of Crystal Growth, Vol.187, p.397-401, (1998).

Baranov P.G., Mokhov E.N., Ostroumov A.O., Ramm M.G., Ramm M.S., Ratnikov V.V., Roenkov A.D., Vodakov Yu.A., Wolfson A.A., Saparin G.V., Karpov S.Yu., Zimina D.V., Makarov Yu.N., Juergensen H. Current status of GaN crystal growth by sublimation sandwich technique. MRS Internet Journal of Nitride Semiconductor Research, Vol.3, Art.50, (1998).

Karpov S.Yu., Makarov Yu.N., Ramm M.S. Effect of elastic strain on growth of ternary group-III nitride compounds. Materials Science Forum, Vol.264-268, p.1189-1192 , (1998)

Egorov Yu.E., Galyukov A.O., Gurevich S.G., Makarov Yu.N., Mokhov E.N., Ramm M.G., Ramm M.S., Roenkov A.D., Segal A.S., Vodakov Yu.A., Vorob'ev A.N., Zhmakin A.I., Virtual reactor as a new tool for modeling and optimization of SiC bulk crystal growth. Materials Science Forum, Vol.264-268, p.61-64, (1998)

1997

Karpov S.Yu., Makarov Yu.N., Ramm M.S., Talalaev R.A., Control of SiC growth and graphitization in sublimation sandwich system. Materials Science and Engineering, Vol.B46, p.340-344, (1997)

Karpov S.Yu., Makarov Yu.N., Mokhov E.N., Ramm M.G., Ramm M.S., Roenkov A.D., Talalaev R.A., Vodakov Yu.A., Analysis of silicon carbide growth by sublimation sandwich method. Journal of Crystal Growth, Vol. 173, p.408-416, (1997)

Karpov S.Yu., Makarov Yu.N., Mokhov E.N., Ramm M.G., Ramm M.S., Roenkov A.D., Talalaev R.A., Vodakov Yu.A., Modelling of species transport and excess phases formation during sublimation growth of SiC in sandwich system. Institute of Physics Conference Series, N 155, Chapt.9, p.655-658, (1997)

S.Yu. Karpov, Yu.N. Makarov, M.S. Ramm, Simulation of Sublimation Growth of SiC Single Crystal. Physica Status Solidi (b), Vol.202, p.201-220, (1997)

Karpov S.Yu., Makarov Yu.N., Ramm M.S. The role of gaseous species in group-III nitride growth. MRS Internet Journal of Nitride Semiconductor Research, Vol.2, Art.45, (1997)

Averyanova M.V., Przhevalskii I.N., Karpov S.Yu., Makarov Yu.N., Ramm M.S., Talalaev R.A. Analysis of vaporization kinetics of group-III nitrides. Materials Science and Engineering, Vol.B43, p.167-171, (1997)

1996

Averyanova M.V., Karpov S.Yu., Makarov Yu.N., Ramm M.S., Talalaev R.A. Theoretical model for analysis and optimization of group III-nitrides growth by molecular beam epitaxy. MRS Internet Journal of Nitride Semiconductor Research, Vol.1, Art.31, (1996)

Karpov S.Yu., Makarov Yu.N., Ramm M.S., Theoretical consideration of Si-droplets and graphite inclusions formation during chemical vapor deposition of SiC epitaxial layers. Institute of Physics Conference Series, N.142, Chapt.1, p.177-180, (1996)

Karpov S.Yu., Makarov Yu.N., Ramm M.S.

Analytical model of silicon carbide growth under free-molecular

transport conditions.

Journal of Crystal Growth, Vol.169, p.491-495, (1996)