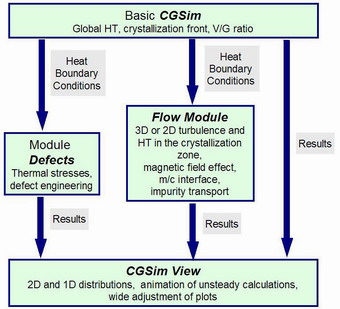

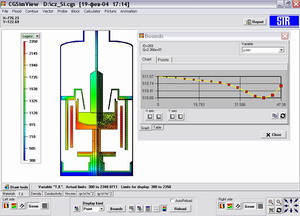

CGSim package for analysis and optimization of Cz, LEC, and VCz growth of semiconductor crystals.

Fig. 1. CGsim

package. |

Download printable version with application examples

The CGSim (Crystal Growth Simulator) code is specialized software for simulation of Czochralski (Cz), Liquid Encapsulated Czochralski (LEC), and Vapor Pressure Controlled Czochralski (VCz) growth. The code provides information to growers on the most important physical processes responsible for crystal growth and quality. The CGSim package contains several modules such as Basic CGSim, Defects, Flow Module, and CGSim View.

Basic CGSim

Capabilities of Basic CGSim include:

- Radiative heat transport

- Conductive heat transport

- Heater power adjustment to provide the required crystallization rate

- Calculation of crystallization front geometry

- Automatic reconstruction of the geometry for several crystal positions

- Special models for anisotropic characteristics of materials

The Basic CGSim program is developed for industries and research teams. Graphical User Interface of the Basic CGSim code requires no special computational skills. All setup and computational steps are highly automated to minimize user efforts.

Work with Basic CGSim includes the following stages:

- Specification of the growth system geometry

- Specification of material properties

- Grid generation

- Boundary condition specification

- Problem mode specification

- Computation process

- Visualization of the results

Below, we will have a closer look at some of these stages.

Geometry Specification

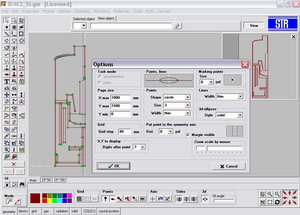

Fig. 2. Specification of

the Growth System in the Graphical User Interface

(GUI) |

Advanced users familiar with AutoCAD can use it as an alternative geometry specification tool and then import the geometry into CGSim using the DXF format.

The CGSim code is a software designed specially

for 2D axisymmetrical computations,

so the user only needs to create a half of the reactor geometry.

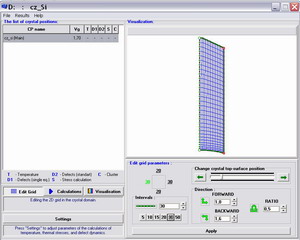

Grid Generation

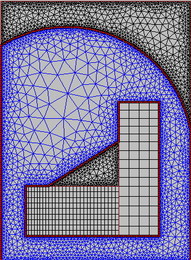

The built-in geometry analyzer automatically recognizes closed contours as blocks, which substantially facilitates the geometry pre-treatment. This feature is also very useful as a diagnostics tool—if some area of the geometry, that stands for a separate construction element or a closed gas volume is not recognized as a block, it means that the contour representing its boundary is not closed. At the next step, the user can quickly generate a grid for the whole system using the auto grid generator. Since the automatic grid generator is very robust, the user only needs to set a parameter characterizing desired grid refinement to start the grid generation. GUI also provides the user with several options, facilitating the choice of blocks and grid types for the automatic grid generation. For instance, the user can choose the grid of some type to be generated in gas or solid blocks only.

Advanced users can customize the mesh manually in selected blocks or throughout the whole system. The grid generator supports triangular and quadrangular grids with both matched and mismatched interfaces. These capabilities are especially important for modeling of the crystallization front geometry, when structured grids are required on both sides of the interface. Local refinement of structured grids can be achieved through refining the node distribution on the respective edges towards one of the ends or symmetrically. For unstructured grids, refinement can also be regulated through the grid quality parameters.

|

|

|

Fig. 3. Examples of grids generated by Basic CGSim

| |

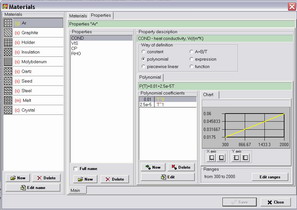

Materials

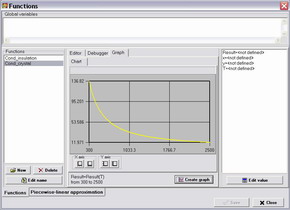

The CGSim tool for setting characteristics of materials

gives the user wide possibilities. One can choose a constant, a polynomial function, a piecewise linear function,

expression, or an arbitrary function, which can be programmed in the Function window. Plots for

all characteristics can be displayed in the same window.

For example, the heat conductivity can be defined as a function of temperature

and coordinates in an arbitrary way borrowed from literature. Incorporated programming

language similar to Pascal, extended by preprocessor and visualization of the function,

allows this for user.

|

|

|

Fig. 4. Assigning the Material Properties in GUI

| |

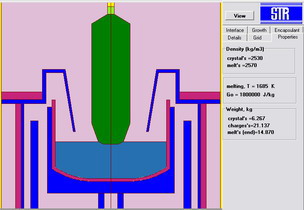

After the geometry creation and the material specification, Basic CGSim calculates the crystal and melt weights, and the initial charge weight, which helps the user to draw crystallization zone geometry. Beside the global heat computations with the given heater powers, Basic CGSim allows searching the powers providing a certain crystallization rate and prediction of crystallization front geometry.

The code permits automatic reconstruction of the geometry

for several crystal positions. To make it, the user has to build

only the geometry with the highest crystal position and to specify

the crystal heights to be computed.

Fig. 5. Crystal and Melt Weight

Calculation |

Fig. 6. Automatic Reconstruction of

the Crystal Positions |

Module Defects

Module Defects is a part of the CGSim package specially designed for analysis of

- thermal elastic stress distribution

- behavior of initial defects such as self-interstitials and vacancies in silicon crystals

- cluster distribution in silicon crystals (voids and oxygen precipitates).

Elastic Stress analysis

Fig. 7. Module Defects

Window |

- zero pressure is assigned along the crystal external boundary;

- radial component of deformation vector ur is equal to zero along the symmetry axis;

- radial component of the force is equal to zero along the symmetry axis.

Several parameters can be used by the user to characterize strain-stress state in the crystal:

- maximum smax and minimum smin principal stresses;

- maximum shear stress sshmax which is critical for the gliding dislocation multiplication;

- Von-Mises stress sVM governing the change of crystal shape.

Simulation of initial defect incorporation

Initial lattice defects (single vacancies and self-interstitial atoms)

are the sources for point defect clusterization during a crystal

thermal treatment. Their concentrations determine the crystal quality

to a large extent. The governing equation of initial defect incorporation

into the crystal and their subsequent recombination in a hot region in

vicinity of the crystallization front could be presented as

,

,

where Ceqx is the equilibrium defect

concentration and Cx is the actual defect concentration,

Dx is the defect diffusivity, V is the crystal

pulling rate, ar is the recombination capture radius,

and DG is the recombination free

energy barrier (x = i, n for

self-interstitials and vacancies, respectively).

Model of point defect clusterization

Certain characteristics of point defects formed during the crystal

growth and subsequent wafer annealing are required for further making

the integrated circuits (IC). Voids and oxygen precipitates near wafer

surface can damage precise sub-micron IC elements. The model incorporated

into the module accounts for simultaneous formation and evolution of

voids and oxygen precipitates, allowing prediction of point defect

concentrations and size distributions.

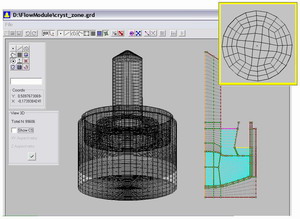

Flow Module

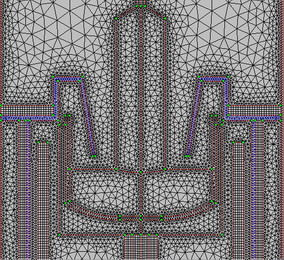

Fig.8.

Automatic 3D Grid Generation from the 2D Grid using octagonal blocks

near the symmetry axis |

- conductive heat transport;

- laminar flow;

- turbulent flow within the RANS, LES,or DNS approaches;

- prediction of crystallization front shape;

- magnetic field effect;

- impurity transport;

- stress computation;

- scalar transport.

Automatic Generation of a 3D Grid

To provide grids for 3D computations, the Flow Module has an automatic 3D grid generator that builds 3D grids on the basis of 2D grids. Not only does it rotate the 2D grid around the vertical axis, but also incorporates blocks with quadragonal horizontal cross section in the central domains of the geometry, providing the area aroud the rotation axis with high-quality grid, see Fig. 8.

Turbulence models

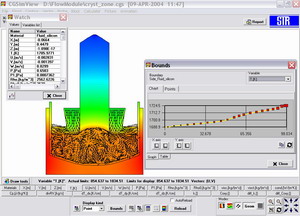

Fig. 9. Flow pattern in the

reactor and 1D temperature distribution along one of the boundaries |

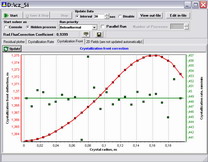

Crystallization front geometry

Flow Module accurately describes the geometry of the crystallization front, temperature gradients, distributions of velocity vectors and scalars, heat and mass fluxes along interfaces. There are options to analyze unsteady effects in several monitoring points and in cross sections of a 3D grid. Parallel version of the solver is also developed for using on Linux clusters or on several PCs in a Windows network.

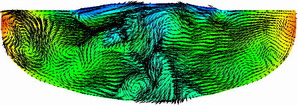

Magnetic field effects

Flow Module was extended by options for calculating magnetic field

effects (MFs) in the crystallization zone, including the conjugated

electric current flow in the crystal and melt]. There are automatic

options for direct current magnetic fields of uniform (vertical or

horizontal) and cusp configurations. Alternative current MFs can be

implemented in a customized software version. Melt flow and the

crystallization front can be analyzed in both 3D unsteady and 2D steady

approaches. The examples on this page are provided for 400 mm diameter Si

CZ growth.

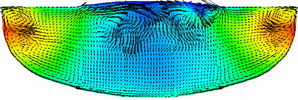

|

|

|

Fig. 10. Temperature distribution and velocity distribution

in the melt for 400 mm diameter Si CZ growth with zero magnetic field (left)

and with horizontal magnetic field of 30 mT (right)

| |

Solution control and visualization

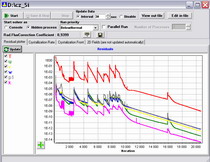

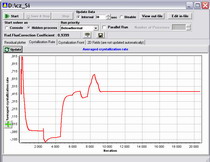

To control the computation execution, there is Computation Manager built-in into the program, which visualizes:

- the equation residuals;

- the averaged crystallization rate;

- the crystallization front shape and the crystallization rate distribution along the melt-crystal interface;

- distributions of the computed variables.

The computations are visualized with the CGSim Viewer

program. Besides, it is possible to store a movie on a hard disk,

showing the time behavior of the flow pattern.

|

|

|

|

Fig. 11. Monitoring of the Computation Progress

| ||

CGSim View

Fig. 12. 1D and 2D Visualization

with CGSim View |

Platforms

The present version of CGSim operates under Windows 2000 and

Windows XP. The solver of Flow Module is available for parallel

computations under Linux.

Additional information

Demo version and code documentation are available upon request.